PC1250-8 Hydraulic Parts Bucket Cylinder 707-01-0J752 For Komatsu Excavator

The 707-01-0J752 hydraulic cylinder is designed for the PC1250-8 excavator, built to handle heavy-duty tasks in challenging environments like construction and mining. It offers exceptional durability, high strength, and resistance to wear and corrosion. Backed by comprehensive after-sales support, including installation guidance and maintenance services, this cylinder ensures reliable performance and longevity. Its robust design makes it ideal for high-pressure and extreme temperature conditions, delivering consistent hydraulic power in demanding work environments.

Product Description

|

Product Name

|

Excavator Hydraulic Bucket Cylinder

|

|

Model

|

PC1250-8

|

|

Part Number

|

707-01-0J752 |

|

Application

|

For Komatsu Excvator Spare Parts

|

|

Temperature Range

|

-20-80°C

|

| Pressure Range |

21 MPa to 35 MPa |

| Dimensions |

Customized |

|

OEM

|

Yes

|

List of Spare Parts

| Pos |

Part No |

Parts name |

|

707-01-0J752 |

Cylinder Assembly |

|

707-01-0J750 |

Cylinder Assembly |

| 1 |

721-13-16120 |

Cylinder |

| 2 |

707-58-11780 |

Rod, Piston |

| 3 |

707-76-10130 |

Bushing China |

| 4 |

07145-00100 |

Seal, Dust, (Kit : K09, K10) China |

| 5 |

07043-00108 |

Plug, Taper |

| 6 |

707-76-10140 |

Bushing China |

| 7 |

208-70-12231 |

Seal, Dust, (Kit : K09, K10) OEM |

| 9 |

707-71-71210 |

Plunger |

| 10 |

707-71-35040 |

Collar |

| 11 |

707-35-91640 |

Ring, Back-up, (Kit : K09, K10) China |

| 12 |

07000-15150 |

O-ring, (Kit : K09, K10) OEM |

| 13 |

707-71-70850 |

Plunger China |

| 14 |

04260-00635 |

Ball, Steel |

| 15 |

707-71-91270 |

Cap |

| 16 |

707-27-16970 |

Head, Cylinder |

| 17 |

707-56-11840 |

Seal, Dust, (Kit : K09, K10) |

| 18 |

707-75-11512 |

Ring, Snap |

| 19 |

707-51-11890 |

Packing, Rod, (Kit : K10) China |

| 19 |

707-51-11050 |

Packing, Rod, (Kit : K09) |

| 20 |

707-51-11690 |

Ring, Buffer, (Kit : K09, K10) |

| 21 |

707-52-11631 |

Bushing |

| 24 |

01010-B2090 |

Bolt China |

| 25 |

707-88-75310 |

Washer |

| 26 |

707-75-10512 |

Ring, Snap |

| 27 |

707-36-16720 |

Piston |

| 28 |

707-44-16150 |

Ring, Piston, (Kit : K09, K10) |

| 29 |

707-39-16120 |

Ring, Wear, (Kit : K09, K10) OEM |

| 30 |

707-44-16910 |

Ring China |

| 31 |

07000-B5105 |

O-ring, (Kit : K10) China |

| 31 |

07000-15105 |

O-ring, (Kit : K09) China |

| 32 |

07001-05105 |

Ring, Back-up, (Kit : K09, K10) |

| 33 |

01310-01225 |

Screw |

Company Information

GuangZhou GuoLi Engineering Machinery Co., Ltd. has over 16 years of expertise in manufacturing high-quality excavator hydraulic cylinders. As a leading foreign trade company, we offer a wide range of products, including arm cylinders, boom cylinders, bucket cylinders, cylinder tubes, rods, custom hydraulic cylinders, seal kits, hydraulic pumps, and electrical components, designed for various excavator models. Our products are exported to more than 100 countries across the globe.

We pride ourselves on having a fully integrated production line for hydraulic cylinders, covering every stage from design to manufacturing. Over the years, we’ve enhanced our offerings to include multi-stage hydraulic cylinders and provide highly customized solutions to meet our clients' needs. Utilizing advanced CNC lathes, grinders, and assembly equipment, we ensure that all our products are produced in compliance with ISO quality standards for superior durability and performance.

Factory Tour

Piston Rod Production Process

| Feature |

Description |

| Material |

Tempered steel |

| Surface Treatment |

Induction hardened before chrome plating to prevent bending and scratching |

| Rust Resistance |

Resists rust for over 100 hours in salt spray tests |

| Production Process |

Produced and electroplated in-house |

| Finish |

Mirror finish technology |

Automatic Welding Process

| Feature |

Description |

| Welding Method |

Fully automated welding for consistency and integrity |

| Craftsmanship |

Lean welding craft ensures strong joint strength and eliminates defects |

| Weld Seam Quality |

Weld seam matches the appearance of original parts |

| Durability |

Welded parts are not easy to fall off |

Finished Product Warehouse Display

Exhibition Showcase

Our Presence at Major Exhibitions: 2023 Malaysia & 2024 Shanghai Bauma

Exhibition With Cooperated Clients

Certificates

Certification

FAQ

1.How can I be sure the part will fit my excavator ?

2.What material do you use on hydraulic cylinder?

-

High frequency quenching No.40 manganese steel as rod material so the cylinder rod has better bending resistance.

-

No.25 manganese steel as tube material ,so the tube has better wear resistance,

High-strength hardened steel as rod head and tube head ,so the cylinder head and rod head more durable.

-

Name-brand seal kits to reduce the hydraulic cylinder oil leakage rate.

3.How long can an order delivery?

-

For some often used models of excavator hydraulic cylinder , we have in stock, within 7 days .

-

For any order less than one container takes about 2 weeks to finish; Order of 1-2 container takes 4 -6weeks.

-

At busy manufacturing season, manufacturing time needs more which can confirm by discussion.

4.How to pay?

-

Order less than 3000USD, full payment at order, Order over USD3000 value ,50% deposited in to start,

50% balance paid to deliver,inspection service accepted.

-

For customized order, 70%payment as deposit ,30% balance paid to deliver.

5.How to delivery?

-

If you have shipping agent ,we will cooperate with your agent to arrange shipment .

-

If not , we have good relationships with shipping companies, express suppliers.

-

For light goods ,by UPS/DHL/TNT(DAP terms) , For heavy goods ,by sea (FOB,CIF,CFR)

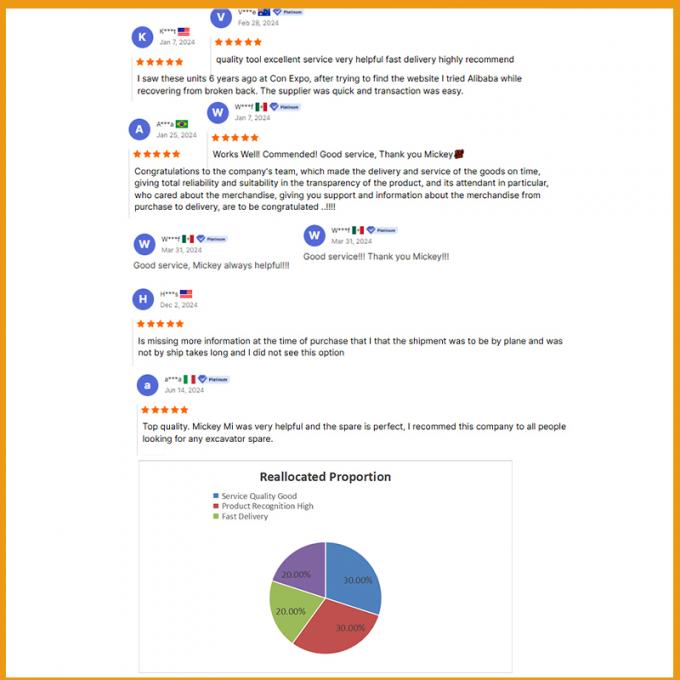

Customer Reviews

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!