China DH220-5 Bucket Cylinder Factory For Daewoo Doosan Excavator Heavy Equipment Parts

The DH220-5 Bucket Cylinder is a high-performance hydraulic cylinder designed specifically for the DH220-5 series excavators. This bucket cylinder plays a crucial role in controlling the movement of the bucket, allowing for smooth and efficient digging, lifting, and material handling.

Product Description

|

Product Name

|

Excvator Hydraulic Bucket Cylinder

|

|

Model

|

DH220-5

|

|

Temperature Range

|

-20-80°C

|

| Pressure Range |

21 MPa to 35 MPa |

| Dimensions |

Customized |

|

OEM

|

Yes

|

Other Excavator Models Of Various Brands

More Other Daewoo Or Doosan Model We Can Provide

| Brand |

Models |

| Doosan / Daewoo |

SL018-VT, DH35, DH55-V, DH55G, DH50-7, DH55D, DH60, DH60-7, DH60LC-7, DH70, DH80, DH130, DH150, DH150W-9, DH215-5, DH200-5, DH150LC-7, DH215-7, DH220-5, DH220-7, DH220-9, DH220-10, DH225-9, DH258, DH258LC-7, DH280, DH290B, DH300-5, DH300-7, DH320, DH360, DH370, DH500, DX300, DX17Z, DX55-9C, DX60, DX60-9C, DX60E-9C, DX65-9C, DX75-9C, DX150, DX170, DX220, DX220LC-9C, DX225LCV, DX330, DX380LC-9C, DX420, DX500, Solar S200, S220, S250, S300, S330 |

Maintenance and Repair

Regular inspection, appropriate lubrication, seal replacement, and calibration checks are common maintenance tasks that should be performed on bucket cylinders. Proper installation, lubrication, and adjustment are essential to ensure the longevity of the cylinder. Proper alignment and the use of suitable installation brackets can help secure the cylinder. Recommended inspection, repair, and replacement procedures are provided, along with tips for increasing the lifespan of the cylinder.

Company Information

GuangZhou GuoLi Engineering Machinery Co., Ltd. is a leading manufacturer specializing in excavator hydraulic cylinders, with over 16 years of experience in the industry. We offer a comprehensive range of products, including crawler excavator arm cylinders, boom cylinders, bucket cylinders, cylinder tubes, rods, custom hydraulic cylinders, seal kits, hydraulic pumps, and electric parts, all designed for various excavator models. Our products are exported to over 100 countries and regions worldwide.

With a complete hydraulic cylinder production line, we handle everything from design to manufacturing. Over the years, we’ve enhanced our offerings to include multi-stage hydraulic cylinders, focusing on customization to meet diverse customer needs. Utilizing advanced CNC lathes, grinders, and assembly equipment, we adhere to strict ISO quality standards to ensure high precision, durability, and performance in all our products.

Professional Expertise

Our team consists of skilled engineers and technicians with extensive experience in the design, production, and testing of hydraulic cylinders, ensuring high-quality solutions for every project.

International Certifications

We hold numerous international certifications, including CE, ISO9001, and SGS, demonstrating our commitment to meeting the highest global quality standards.

Tailored Solutions

We offer customization services to meet the specific needs of our customers, covering everything from design and production to testing, ensuring the perfect fit for your application.

State-of-the-Art Equipment

Equipped with advanced CNC machines and other cutting-edge production tools, we efficiently manufacture hydraulic cylinders with precision and reliability.

Comprehensive After-Sales Support

Our dedicated after-sales service includes technical support, installation guidance, and maintenance & repair services, ensuring your complete satisfaction and long-term performance of our products.

Factory Tour

Piston Rod Production Process

Automatic Welding Process

Finished Product Warehouse Display

Exhibition Showcase

Our Presence at Major Exhibitions: 2023 Malaysia & 2024 Shanghai Bauma

Exhibition With Cooperated Clients

Certificates

Certification

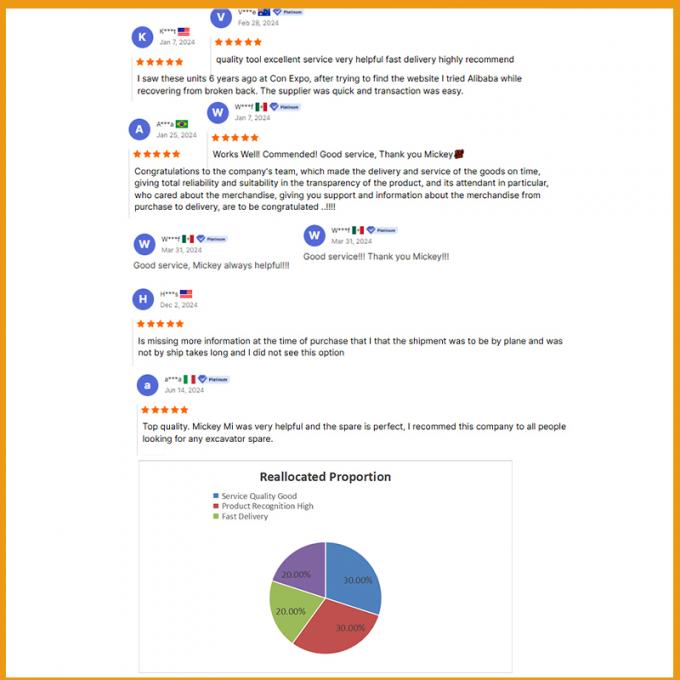

Customer Reviews

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!