Hydraulic Bucket Cylinder For Excavator SH130-5 Sumitomo Excellent Parts

Product Description

This machinery replacement is an original for Sumitomo spare part in Vio80 excavator.

|

Product Name

|

SH130-5 Excavator Bucket Cylinder

|

|

Model

|

SH130-5

|

|

Application

|

For Sumitomo SH130-5 Excavator

|

|

Temperature Range

|

-20-80°C

|

| Pressure Range |

21 MPa to 35 MPa |

| Dimensions |

Customized |

|

OEM

|

Yes

|

| Service Stage |

Details |

| PreSales Service |

Free consultation and technical advice |

| Customization options for dimensions and performance based on customer requirements |

| InSales Service |

Fast production and delivery times |

| Real-time updates on manufacturing and shipment status |

| AfterSales Service |

Warranty on manufacturing defects |

| Technical support for installation and maintenance |

ps.If you are looking for other hydraulic cylinders for Sumitomo , please contact us for a quote

More Cylinder Models For Sumitomo We Provided

| for Sumitomo |

SH50 SH55 SH60 SH65U SH70 SH75 SH80 SH90 SH100 SH120 SH120-3 SH120-5 SH120A1 SH120A2 SH120A3 SH130 SH135 SH145 SH160 SH180 SH200 SH200-1 SH200-3 SH200-3G SH200-5 SH200-A1 SH200-A2 SH200-A3 SH200-C1 SH200-A1 SH200-A2 SH200-A3 SH210 SH210-5 SH220 SH220-2 SH220-3 SH220-5 SH220-7 SH225 SH235 SH240 SH250 SH260 SH265 SH280 SH290-3 SH290-7 SH300 SH300-3 SH300-5 SH300-A2 SH330 SH330-A3 SH340 SH350 SH350-5 SH350-7 SH400 SH450 LS1600FJ2 LS2600FJ2 LS2650 LS2650FJ2 LS2800 LS2800CJ-2 LS2800DJ-2 LS2800EJ-2 LS2800FJ-2 LS2800FJ2 LS2800F2 LS3400 LS3400EA LS3400FJ LS4300 LS4300FJ LX130 LX160 LX210 LX240 L245 LX250 LX300 LX350 SL280FJ |

Cylinder Parts Process

| Process |

Description |

| Piston Rod |

Piston rod conditioning with high-frequency surface hardening, achieving hardness up to 55. Surface treated with hard chromium plating. |

| Rod End, Tube End, Cylinder Cover |

Made of forged steel, with automatic welding for smoother welds instead of manual welding. |

| Cylinder Tube |

Made from 25Mn steel, sandblasted surface, followed by a two-layer paint process with primer and topcoat. |

| Seals |

Imported Japan NOK and US SKF seals, ensuring oil leakage rate below 1%. |

| Assembly |

Fully automated assembly line to reduce manual intervention and improve production stability, preventing nut drop. |

| Final Inspection |

Post-production pressure testing of each cylinder to ensure no oil leakage. |

We can supply you all kinds of excavator spare parts as following

| Hydraulic Parts |

Hydraulic pump,Travel motor,Swing motor,Travel gearbox,Swing gearbox,Main control valve,Hydraulic cylinder assy,Gear pump,Pump regulator,etc |

| Undercarriage Parts |

Track link and shoe assy,Track roller,Carrier roller,Idler,Sprocket,Track link guide,Track Adjuster assy,etc |

| Excavator Attachments |

Bucket,mud bucket,earth bucket,heavy duty rock bucket,skeleton bucket,hydraulic breaker,hydraulic quick coupler,ripper,etc |

| Cabin Parts |

Excavator cabin,Cabin door,Side door panel,Cabin seat,Cabin glass,Engine cover,Tool box,Door lock,etc |

| Electric Parts |

Controller,Monitor,Panel,Throttle motor,Solenoid valve,Wire harness,etc |

| Engine Parts |

Cylinder block,Cylinder head,Crankshaft,Engine assy,Injector,Fuel injection pump,Oil pump,Feed pump,Oil cooler,Filter,Turbocharger,Starter motor,Alternator,Water pump,Fan blade,Liner kits,Bearings,Valves,Gasket kit,etc |

| Other Parts |

Seal kit,Floating seal,Joystick,Foot pedal valve,O-ring box,Coupling,etc |

Company Information

GuangZhou GuoLi Engineering Machinery Co., Ltd., with over 16 years of experience in excavator hydraulic cylinders, is a foreign trade company specializing in a wide range of products, including crawler excavator arm cylinders, boom cylinders, bucket cylinders, cylinder tubes, cylinder rods, custom hydraulic cylinders, seal kits, hydraulic pumps, and electric parts, all designed for various excavator models. Our products have been exported to over 100 countries and regions worldwide.

Factory Tour

Our main product, excavator cylinders, is produced through a complete hydraulic cylinder production line, from design to manufacturing. With over ten years of experience, we’ve upgraded our offerings to multi-stage hydraulic cylinders. We focus on cylinder customization and produce a variety of domestic and imported excavator cylinders. Using advanced CNC lathes, grinders, and assembly equipment, we strictly follow ISO quality standards throughout production.

Piston Rod Production Process

| Feature |

Description |

| Material |

Tempered steel |

| Surface Treatment |

Induction hardened before chrome plating to prevent bending and scratching |

| Rust Resistance |

Resists rust for over 100 hours in salt spray tests |

| Production Process |

Produced and electroplated in-house |

| Finish |

Mirror finish technology |

Automatic Welding Process

| Feature |

Description |

| Welding Method |

Fully automated welding for consistency and integrity |

| Craftsmanship |

Lean welding craft ensures strong joint strength and eliminates defects |

| Weld Seam Quality |

Weld seam matches the appearance of original parts |

| Durability |

Welded parts are not easy to fall off |

Finished Product Warehouse Display

Exhibition Showcase

Our Presence at Major Exhibitions: 2023 Malaysia & 2024 Shanghai Bauma

Exhibition With Cooperated Clients

Certificates

Certification

FAQ

1.How can I be sure the part will fit my excavator ?

2.What material do you use on hydraulic cylinder?

-

High frequency quenching No.40 manganese steel as rod material so the cylinder rod has better bending resistance.

-

No.25 manganese steel as tube material ,so the tube has better wear resistance,

High-strength hardened steel as rod head and tube head ,so the cylinder head and rod head more durable.

-

Name-brand seal kits to reduce the hydraulic cylinder oil leakage rate.

3.How long can an order delivery?

-

For some often used models of excavator hydraulic cylinder , we have in stock, within 7 days .

-

For any order less than one container takes about 2 weeks to finish; Order of 1-2 container takes 4 -6weeks.

-

At busy manufacturing season, manufacturing time needs more which can confirm by discussion.

4.How to pay?

-

Order less than 3000USD, full payment at order, Order over USD3000 value ,50% deposited in to start,

50% balance paid to deliver,inspection service accepted.

-

For customized order, 70%payment as deposit ,30% balance paid to deliver.

5.How to delivery?

-

If you have shipping agent ,we will cooperate with your agent to arrange shipment .

-

If not , we have good relationships with shipping companies, express suppliers.

-

For light goods ,by UPS/DHL/TNT(DAP terms) , For heavy goods ,by sea (FOB,CIF,CFR)

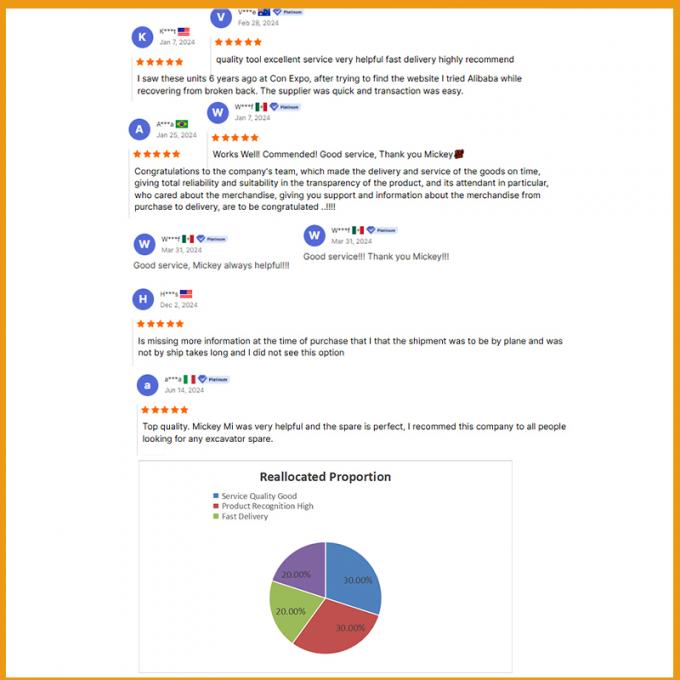

Customer Reviews

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!